Kosalela biloko .

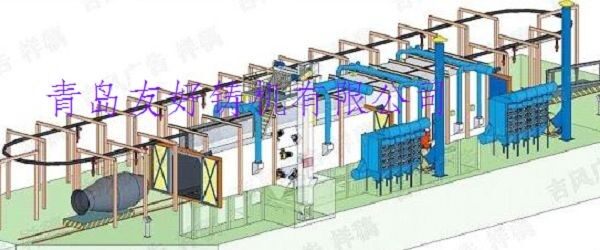

Machine ya bopeto ya Blasting ya crochet ya crochet esalemaka mingi mingi na ba castings ya minene, ba compartiments ya camion, ba machines ya mine ya charbon, ba machines ya construction, ba machines ya construction na ba industries misusu.

The working principle of the hook-pass shot blasting machine is: the large workpiece is lifted by two variable frequency speed-regulating electric hoists to quickly reach the cleaning room, and then passes through the shot blasting room slowly. The shot blaster cleans the whole body of the large component, and enters the rear attachment room after shot blasting. In the rear payment room, the uncleared dead corners of the workpiece are manually shot blasted by a shot Réservoir ya Blasting. Nsima ya bopeto, ba levages électriques mibale oyo ezali ko réguler na fréquence variable epusaka pièce ya mosala mpo na kokende noki na station ya déchargement mpo na ko décharger matériel; the small workpiece is lifted by one variable frequency speed-regulating electric hoist to quickly arrive at the cleaning room, and the workpiece autobiography device drives the workpiece to rotate, and the small parts are shot blasted. The electric hoist drives the workpiece to quickly move to the unloading station to unload the material. The dust generated in the entire shot blasting cleaning process is processed by the dust collector and discharged to meet the Mibeko.

Track ya crochet e adopter structure ya bague, mpe levage électrique après déchargement ezongaka noki na niveau ya chargement. en utilisant plus de 3 groupes ya ba levages électriques ekoki ko réaliser chargement, shot blasting mpe déchargement ya ba lignes ya assemblage, ko améliorer effet mpe efficacité ya Blasting.

Usage: Machine ya Blasting ya Série ya Série Q37 Shot esalemaka mingi mingi pona bopeto ya likolo pe kolendisa ba pièces structurelles ya acier, ba castings, ba pièces ya machines ya construction pe ba pièces misusu.

Avantages ya Machine ya Blasting ya Shot ya Hook Pass .

1. Salelá dispositif ya Blasting ya lisasi ya Centrifuge ya National Cantilever na volume ya Blasting ya masasi ya monene mpe vitesse ya masasi ya likolo mpo na kobongisa taux ya bopeto mpe qualité ya bopeto.

2. Diagramme ya projectile simulé ya ba dimensions misato mpe ba dessins nionso ya machine ya Blasting ya masasi esalemi na nzela ya conception assistée par ordinateur (CAD, SW), mpe pona mpe bobongisi ya dispositif ya Blasting ya masasi ezali na raison mingi mpo na ko assurer que ba pièces ya mosala ya minene esukolami na mbala moko.

3. Salelá ba slings ya kotombola ya kilo, mpe crochet ezali na misala ya kotombola, kopota mbangu mpe rotation ya kati.

4. Ba plaques ya acier manganèse ya chrome ya likolo ekoki kosalelama mpo na bobateli engebene na masengi ya bakiliya, to ba plaques ya bobateli ya alliage en masse oyo ekoki kolatisama te ekoki kosalelama. Bomoi ya mosala ebongisami mingi, mpe lolenge ya komonana ezali kitoko mpe pete mpo na kozongisa.

Paramètres techniques ya crochet oyo ezali koleka na nzela ya machine à blasting shot .

|

Numéro de série . |

Mosala |

Modele |

QH3730 |

QH3750 |

QH37100 |

|

1 |

Poids ya chargement ya voiture . |

t |

6 |

10 |

10 |

|

2 |

Kilo ya crochet moko . |

t |

3 |

5 |

10 |

|

3 |

Massage . |

KG . |

8000 |

13000 |

15000 |

|

4 |

Shot Blasting Quantité . |

kg/min . |

8*200 |

12*200 |

12*250 |

|

5 |

Ventilation . |

m3/h |

20000 |

28000 |

27000 |

|

6 |

Kilo mobimba . |

t |

94 |

106.5 |

155.5 |

|

7 |

Nguya ya mobimba . |

KW . |

360 |

385 |

460 |