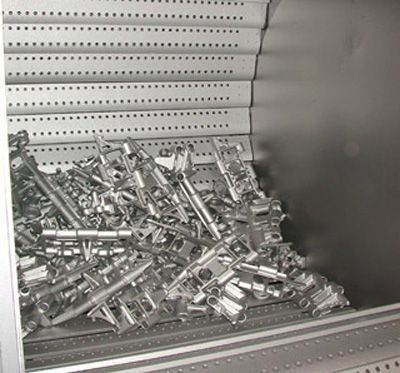

Machine à exploser à crawler en métal .

Metal crawler shot Blasting Machine ya bopeto esalelaka: Ebongi mpo na kosukola likolo ya biteni ndenge na ndenge. Gamme ya application ya crawler shot Blasting Machines ezali monene mingi. Machines ya Blasting ya masasi ezali mingimingi ba fondries, ba usines ya traitement ya molunge, ba usines ya moteur, ba usines ya ba machines à outils, ba usines ya ba pièces ya vélo, ba usines ya ba machines ya puissance, ba usines ya ba pièces ya ba voitures, ba usines ya ba pièces ya motuka, ba factoriels ya moto te etc.

Machine ya explosion ya crawler ya métal esalela roulette rotative ya vitesse makasi mpo na kobwaka ba projectiles epai ya eloko ya mosala oyo ebalukaka continuellement na tambour mpo na kozua tina ya bopeto. Ebongi mpo na kopelisa masasi, kolongolama ya ba échelles ya oxyde mpe ko renforcer surface ya ba castings ya mike, ya ko tabac. Collision. Ba castings ebetamaka na Blasted mpo na ko faciliter processus ya traitement mécanique ya se, oyo ekoki ko sauver temps ya traitement mpe kobatela ba machines outils mpe ba outils na ba dégâts; Nsima ya kopakola langi na esika oyo esalemi te, ekolongola te ntango molai, ekobongisa bomoi ya mosala mpe lolenge ya komonana ya biloko .

Principe ya mosala ya machine ya ko exploser na crawler ya métal .

In the cleaning room, use a feeding mechanism to add no more than the specified number of workpieces. After the machine is started, the workpiece is turned over by the metal track. At the same time, the high-speed projectile thrown by the shot blaster forms a projectile bundle, which evenly hits the workpiece surface, so that the workpiece is cleaned. After the shot blasting is cleaned, the workpiece can be unloaded from Tambour na mécanisme ya décharge na ko reverser piste, yango wana machine ebongi mingi pona intégration na ligne automatique ya production.

Ba projectiles oyo ebwakami mpe ba particules ya zelo esopanaka na kati ya matiti ya plaque ya bibende na nse na nzela ya esika oyo ezali kati na banzela ya bibende mpe mabulu ya mike na plaque ya nzela, mpe etindami na kati ya elevateur na nzela ya convoyeur ya vis, mpe na nsima ekabolami na kati ya separateur. mputulu emɛlami na ventilateur mpe etindami na molangi ya mputulu. nsima ya filtrage na kati ya aspoir na kati ya ambiance, mopepe ya bopeto ezali kobima na kati ya mopepe ya bopeto, mopepe ezali kobima na kati ya mopepe ya bopeto, mopepe ezali kobima na kati ya mopepe ya bopeto, mopepe ezali kobima na kati ya mopepe ya bopeto, mopepe ezali kobima na kati ya mopepe ya bopeto, mopepe ezali kobima na kati ya mopepe ya bopeto, mopepe ezali kobima na kati ya ambiance. collector box at the bottom of the dust collector by backblowing. The user can remove it regularly. The waste sand flows out from the waste pipe for reuse. The pellet sand mixture is retracted from the reuse tube and entered the chamber body. After the separator is separated, the clean projectile enters the shot blaster through the ballast supply gate of the ballast supply system and throws the workpiece Kotambola na yango. .

Paramètres techniques ya machine à blasser à crawler métallique .

| Nimero | Motángo ya série Item . |

Lolenge |

QR3210 |

15gn . |

28gn |

|

|

1 |

Productivité . |

T/h |

1.0-1.8 |

5-6 |

8-12 |

|

|

2 |

Makoki ya koleisa . |

KG . |

600 |

1500 |

2800 |

|

|

3 |

Kilo ya likolo ya eteni moko . |

KG . |

50 |

230 |

360 |

|

|

4 |

Diamètre ya disque ya suka . |

mm . |

1000 |

1092 |

1245 |

|

|

5 |

Volume oyo ezali malamu . |

m |

0.3 |

0.45 |

0.8 |

|

|

6 |

Capacité ya Blasting ya masasi . |

kg/min . |

250 |

450 |

700 |

|

|

7 |

Volume ya mopepe ya kolongola mputulu . |

m3/h |

6000 |

6000 |

8000 |

|

|

8 |

Consommation ya puissance . |

KW . |

32.6 |

49.3 |

64.5 |

|

|

9 |

Bolai . |

m |

3.6x2.9x4.7 |

4.6x3.2x5.8 |

5.3x4.5x6.8 |